Midwest Con - Future of Data Hackathon Medals and Box

During my internship with Kaleidoscope Innovation I designed and manufactured a medal and box. The medal is for the winners of the Future of Data Hackathon and features a box with a dynamic kinetic user experience. Theses were presented by Kaleidoscope at Midwest Con.

Skills Used: Sketching, Prototyping, Wood Working, Design for Manufacturing, Solid Works, Keyshot.

Intro

Midwest Con is a tech conference that highlights policy, innovation, and social impact, in real projects. One event hosted is the Future of Data Hackathon.

Teams compete in the hackathon where they create tech solutions in the fields of blockchain, AI, and data visualization.

As a sponsor of the event, Kaleidoscope is creating medals for first second and third place in the hackathon.

“Midwest Con is where algorithms meet empathy and

The Human Code guides the architecture of tomorrow.”

Design Criteria

Medal must include the Midwest Con logo.

Medal must include the Future of Data Hackathon logo.

Medal must indicate first, second and third place.

Development

Explored medal shape, placement of logos, and arrangement of words.

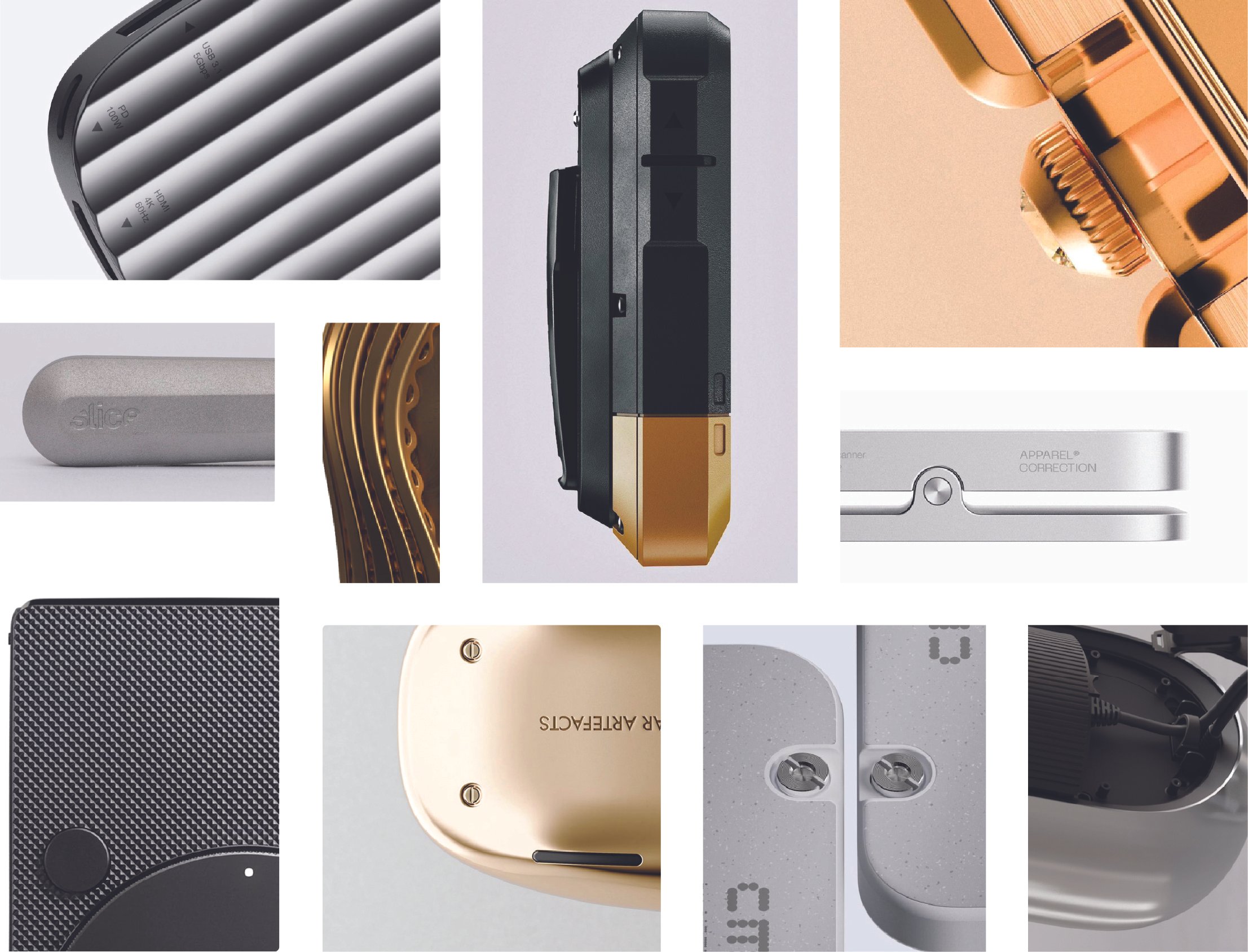

Materiality Exploration

Gold, silver and bronze medal, complimented by black.

Explored plain metal materiality, layering and resin filled.

Design for Manufacturability

In the milling process I had to consider the minimum bit radius. For my process the minimum radius was .05mm.

The milling method used was inset milling, rather than proud, for ease of manufacturing.

To make the smaller print legible, I filled it with black resin to increase contrast.

Final Medals

Bronze (front), Silver (back) and Gold (front).

Keyshot Renders

Box Development

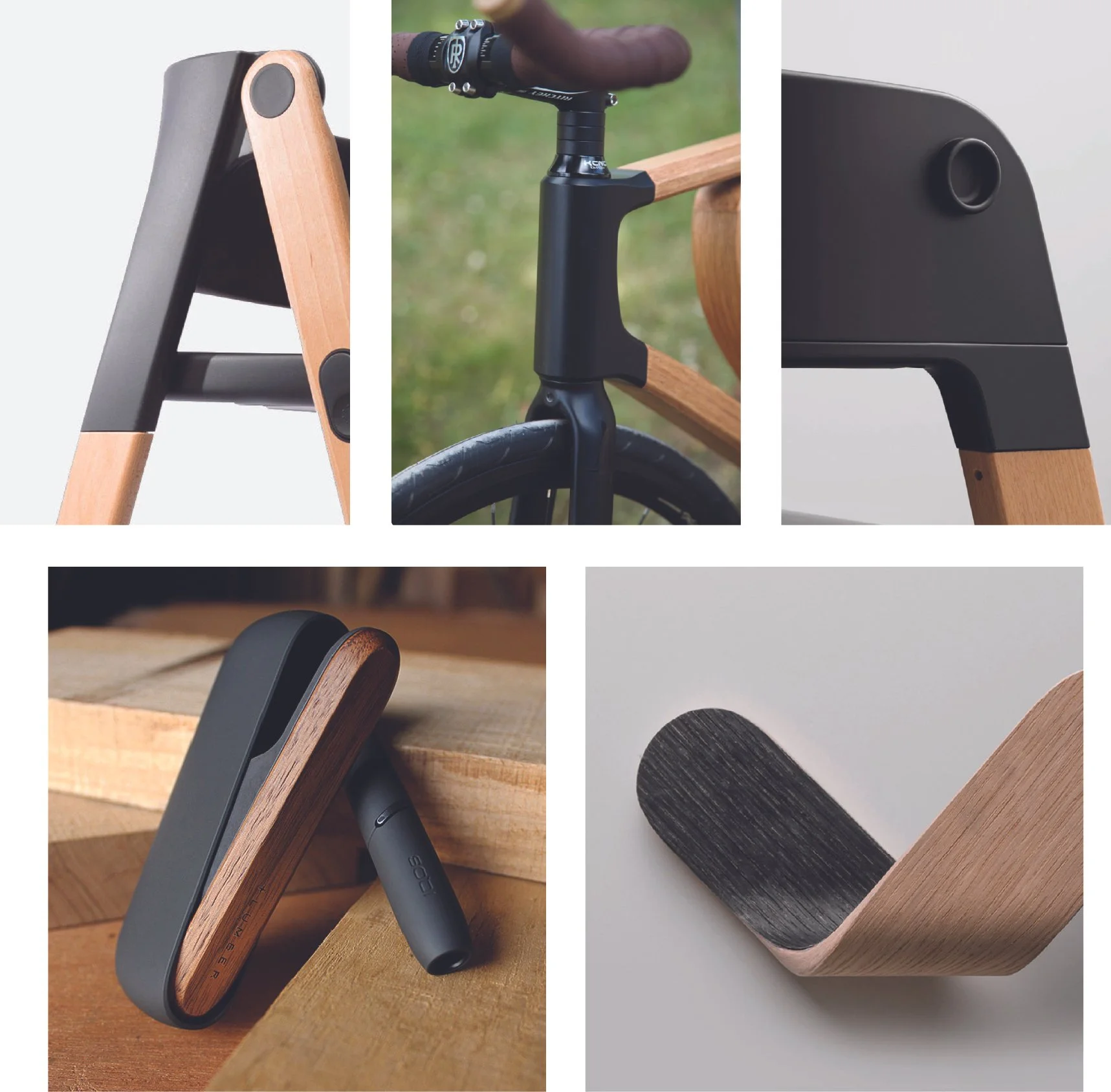

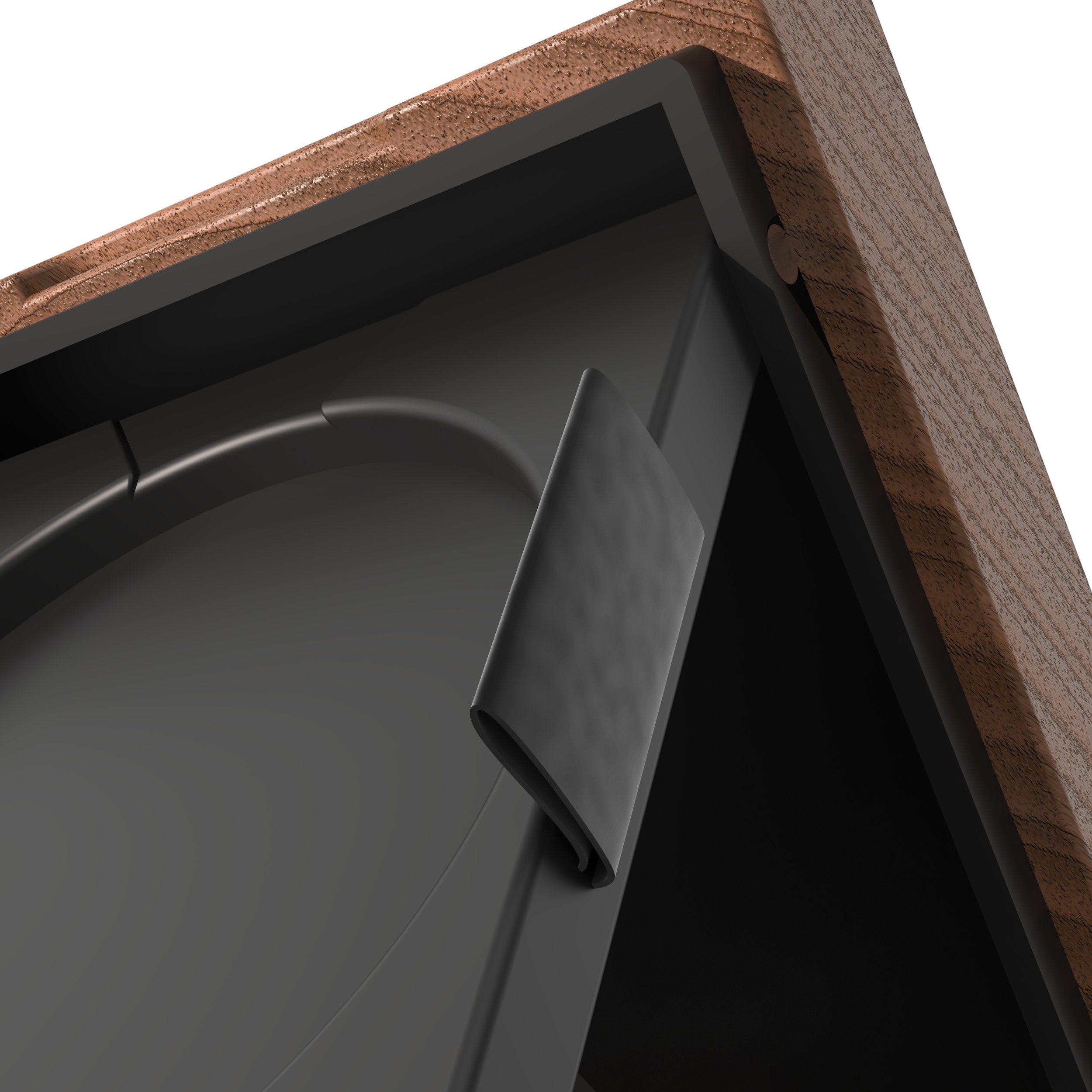

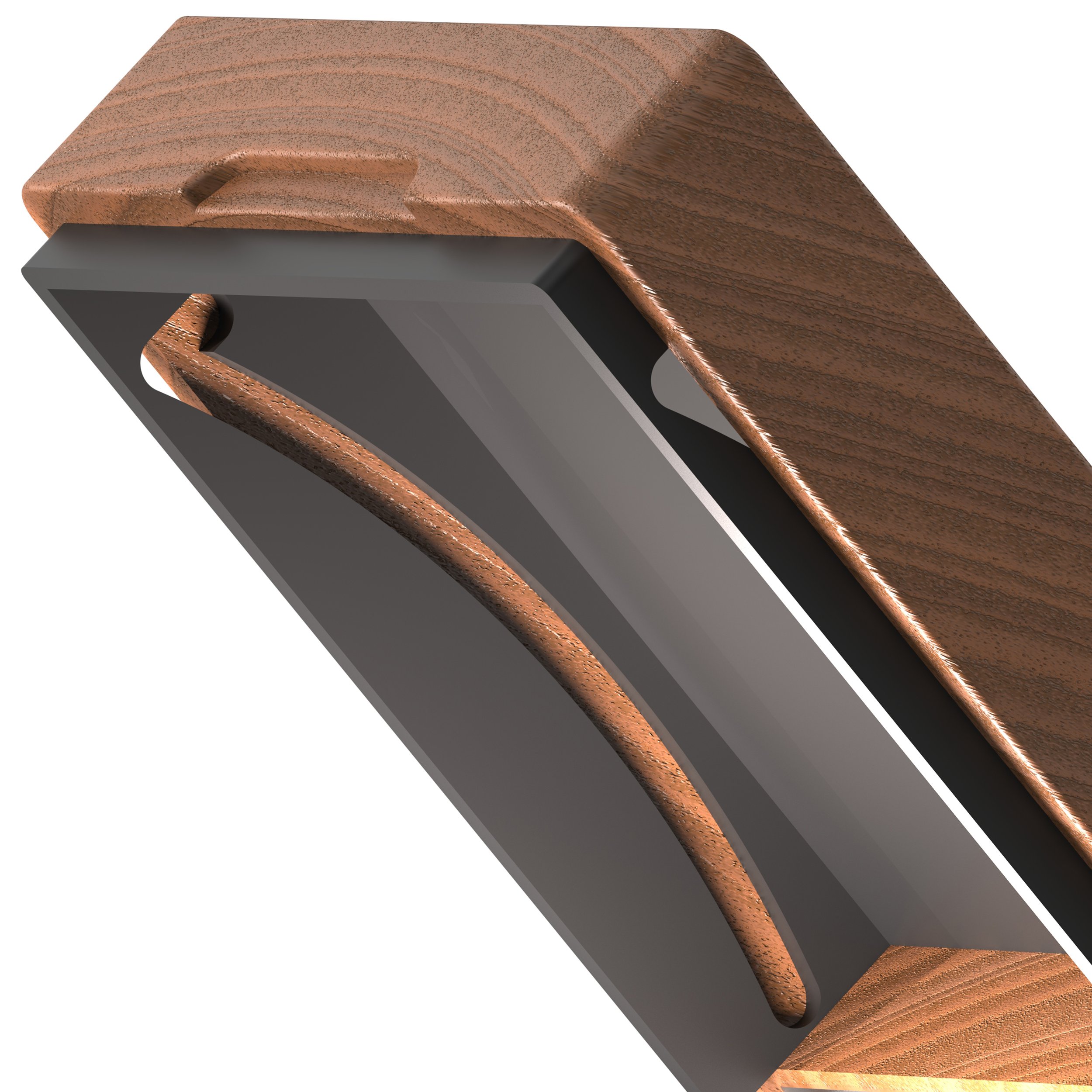

Explored different mechanisms, stagnate vs kinetic experiences, and different display states.

Materiality Exploration

Dark wood with black interior, referencing black used in medal.

Explored wood stains for exterior, and fabric and plastic materiality for interior.

Design for Manufacturability

For manufacturing the box, I wanted a mix of 3D printed parts and wooden parts. I chose to make the interior mechanism 3D printed.

The biggest challenge was making the cam and track mechanism. I wanted to create an engaging kinetic experience for the user. To achieve that much care was put into the mechanism.

To manufacture the wooden box, I used hard wood that was carved using a CNC machine.

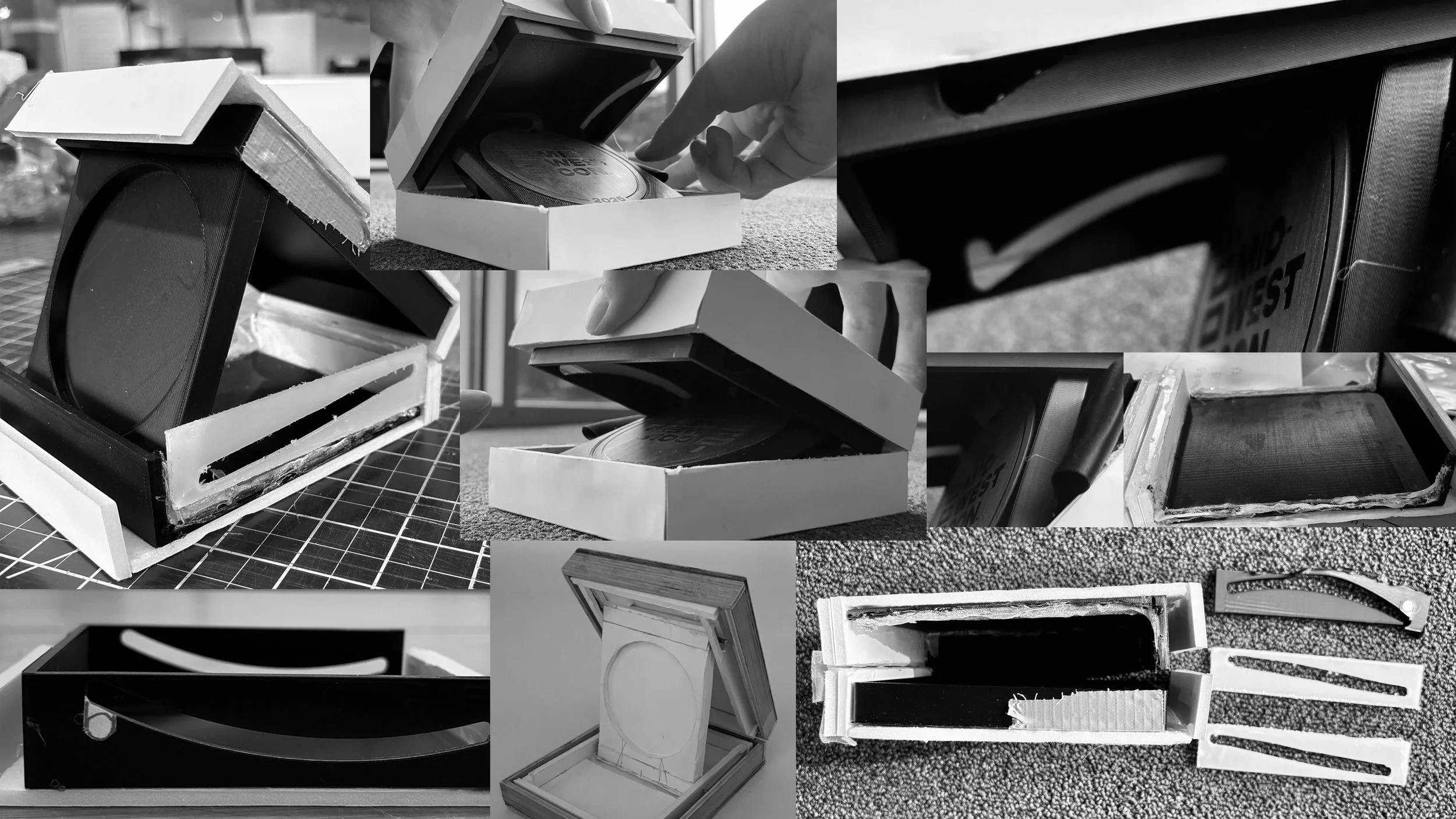

Cam Mechanism Prototyping

While my mechanism worked in CAD, when I moved into physical prototyping, the pin was stalling in the slot.

The vector of the pin reaches a vector perpendicular to the track causing the pin to be unable to translate smoothly through the track.

To fix this problem I explored solutions such as different track shapes and linkage systems. My final solution was to prompt the user to pull the cam along the track creating a two-step opening experience.

Final Box

Opening of box with working cam mechanism.

Final box in display position with medal.